EU Project Revolutionises Green Hydrogen Production

Brussels, Wednesday, 24 September 2025.

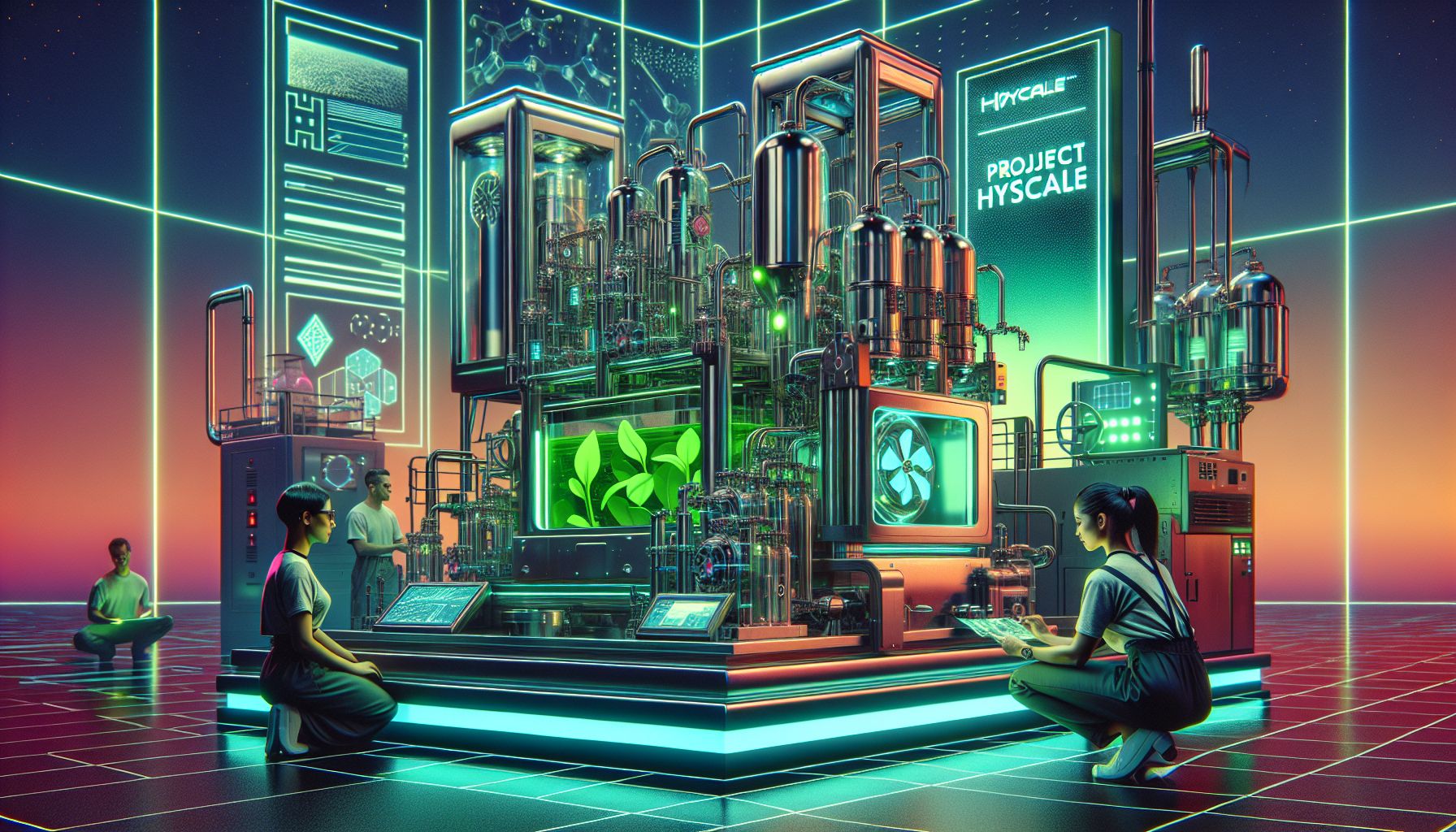

The EU-backed HYScale project has cracked the code to make green hydrogen more affordable and scalable. This leap in electrolysis tech might just turbocharge our sustainable energy transition.

Breaking the Barriers with Electrolysis

Let me tell you, the HYScale project is like that overachieving student in class who just cracked the toughest code in green hydrogen production. By refining electrolysis technology, they have significantly reduced hydrogen permeability, which was once a bottleneck for scaling anion exchange membranes (AEMs). This breakthrough means we’re looking at the production of 100kW stacks without the usual membrane supply constraints [1].

From Lab to Reality

The project isn’t stopping there. They’ve moved from laboratory-scale productions to a point where they can produce batch volumes sufficient for industrial applications. Dr. Julien Fage of CENmat highlighted that this scalability is paving the way for multi-kilowatt and soon multi-megawatt systems [1]. Now that’s what I call progress!

A Collaborative Effort

The German Aerospace Center (DLR) has also played a crucial role by finalising the digital design for a 100kW HYScale stack demonstrator. This blueprint not only outlines the dimensioning and material selection but also aims to achieve Technology Readiness Level 5 (TRL 5) [1]. The project’s collaborative effort is a testament to the saying, ‘Teamwork makes the dream work.’

Real-World Applications

What makes this development even more exciting is its potential for real-world application. The focus has shifted from just creating better materials to making them functional in actual production environments. Jagoda Manss-Chmielarz from DLR emphasised that the goal is to deliver scalable, mass-manufacturable solutions for green hydrogen [1].

Implications for Industrial Scale

The advancements made by the HYScale project are a significant step towards making green hydrogen production not only cost-competitive but also industrially scalable [1]. Imagine a future where green hydrogen is as common as your daily coffee—well, we’re moving closer to that reality.